How Amin Renewables Boosted Clean Energy Output and Improved Visibility

“When The Asset Guardian (TAG) was incorporated in our plant, it helped a lot with the consumption of spare parts and inventory, which helps keep the plant up for much longer and better time.” Balan V. Kumar, General Manager, Amin Renewables

Photo courtesy of Amin Renewables

What you will learn in this article:

How Amin Renewables used TAG and Microsoft Business Central to reduce downtime in high-heat solar environments

The role of real-time string-level tracking and alerts in protecting clean energy output

How Enterprise Asset Management (EAM) integrates with ERP systems to connect maintenance, inventory, and finance

Ways Balan Vasant Kumar and his team improved operational sustainability through smarter inventory and failure prediction

How Medlar’s EAM-ERP implementation expertise helped bring everything together

How tools like IoT, Power BI, Copilot, and AI-powered assistance in TAG Mobi, are enabling future-ready asset management

From the desert to the dashboard: meet Amin Renewables

In the heart of Oman’s solar energy landscape, Amin Renewables is lighting the way toward a cleaner future. Located near Nimr in the Al Wusta Governorate, the Amin Solar PV Park spans 4 square kilometers and is equipped with over 337,000 solar panels, generating up to 125 megawatts of clean energy.

Operating in a remote location with extreme conditions meant even minor issues could quickly turn into costly problems. At this scale, every second of uptime matters, and every asset must perform at its peak.

With global solar demand expected to increase by 2030, making efficient asset management is more essential than ever.

Many equipment groups are under constant demand, making maintenance an important mission. Leading that mission is expert Balan Vasant Kumar, overseeing everything from tracker performance to inventory purchase precision.

When downtime isn’t an option in solar asset management

Operating in high-heat conditions where temperatures can climb above 113 °F and equipment is exposed to constant dusty desert winds, Amin Renewables was faced with long procurement timelines and mounting pressure. Equipment failures were hard to predict, spare parts took too long to source, maintenance lacked structure, and data was disconnected from finance.

“The previous system that we had was unable to work out factors like Mean Time Between Failures (MTBF),” explains Balan Vasant Kumar, Maintenance Lead at Amin Renewables. “It’s a very critical tool when working with maintenance.”

Without that visibility, the team was stuck in a reactive loop, costing time, money, and production uptime.

Performance that doesn’t leave clean energy (or string data) on the table

In a string-based solar setup, one weak link can compromise the whole system. If just one string overheats or malfunctions, it disrupts power delivery to the inverter, cutting off clean energy generation from that entire section.

Balan relies on TAG’s real-time data and alerts to monitor performance at the string level. The system continuously tracks critical electrical values, flagging anomalies before they cause damage.

“If the current is high, it results in the string burning,” he explains. “That means a portion of the tracker will not be supplying current to the inverter for getting clean energy. So that is why it's very important for me to track all these things and repair the broken parts.”

Thanks to TAG’s alerting system, Balan and his team are immediately notified when electrical readings deviate from expected values.

If a string shows abnormally high current or irregular voltage, the system triggers a targeted alert. From there, the maintenance team receives a detailed work order through TAG, including the string ID, location, and recommended action.

Technicians are dispatched with the right tools and parts in hand, reducing time spent troubleshooting on-site. Once the issue is resolved, whether it’s a burnt connector, a damaged fuse, or overheated cabling, the fix is logged in TAG’s history, feeding data back into future planning.

This loop helps Balan’s team close the gap between detection and action, preventing small issues from escalating into energy loss.

Photo courtesy of Amin Renewables.

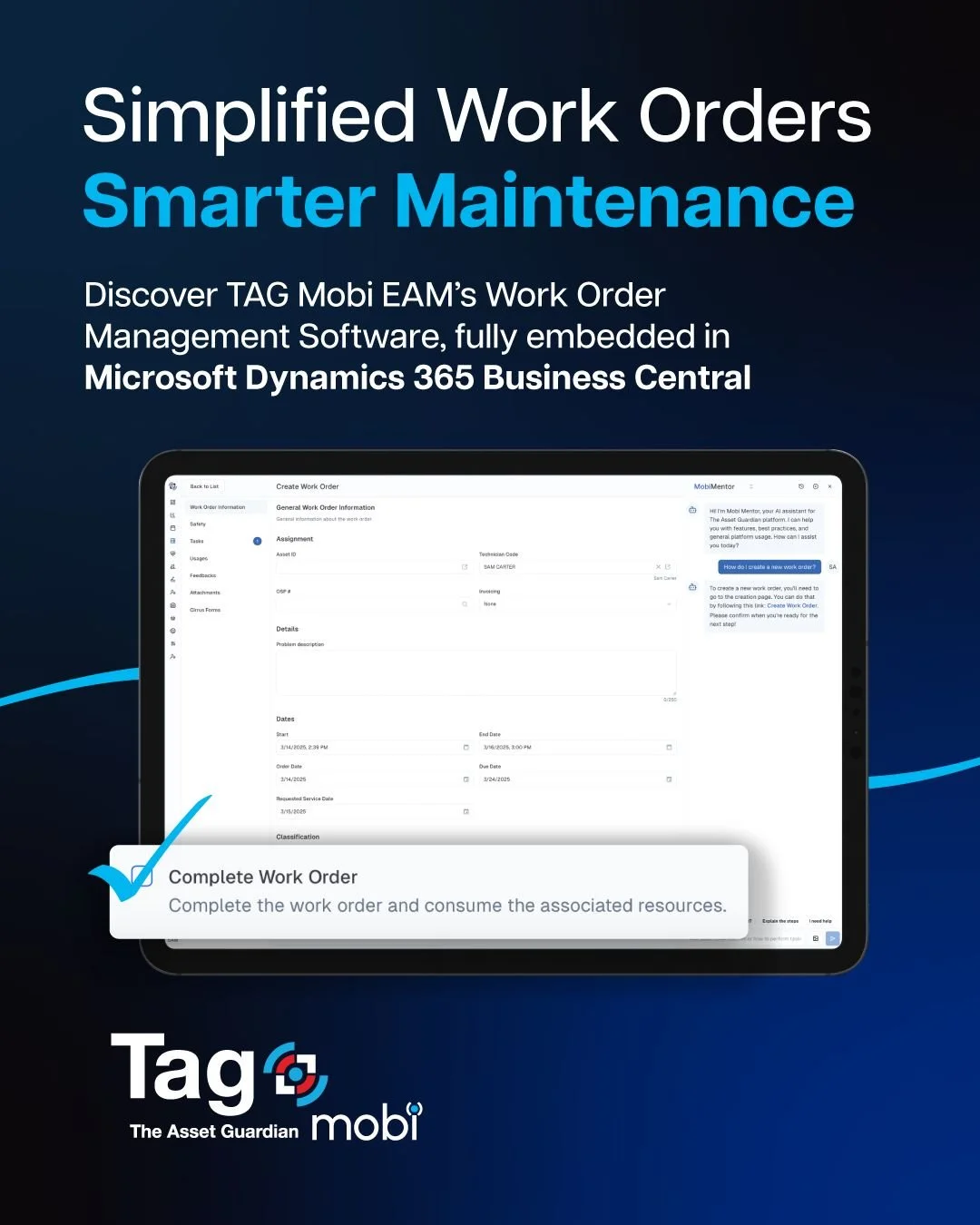

Smarter, cleaner, faster asset management

With The Asset Guardian (TAG) fully integrated alongside Microsoft Dynamics 365 Business Central, Balan Vasant Kumar finally had the tools he needed to optimize performance on his terms.

The implementation, led by Medlar’s team of experts, ensured a smooth transition and setup tailored to Amin Renewables’ needs.

With the right systems and partners in place, Balan could now track consumption patterns in real time, predict failures before they happen, respond faster to alerts that mattered most, and minimize downtime while maximizing inventory efficiency.

“It has helped me make the environment cleaner, better, and more sustainable,” says Balan. “We can reduce downtime because of the support I get from the data and alerts with The Asset Guardian (TAG) in Microsoft Business Central.”

EAM built for Microsoft Dynamics 365 Business Central

One of the reasons this implementation worked so well for Amin Renewables was TAG’s deep integration with Microsoft Dynamics 365 Business Central. As an enterprise asset management (EAM) solution, TAG connects maintenance with the broader business: linking asset data to purchasing, inventory, and finance in real time.

For Balan, that meant maintenance activities were no longer siloed. They were part of a larger system built for coordination and visibility.

“With TAG, consumption is tracked and as soon as the inventory levels go down, it's appropriately flagged at the right moment so that our procurement team takes action in time,” Balan explained. “And so we reduced downtime because of this.”

This EAM approach made it easier to track costs, manage spare parts, and ensure the right information reached the right people at the right time. Instead of juggling multiple disconnected tools, Balan could now make real-time decisions in one unified ecosystem.

Photo courtesy of Amin Renewables.

Asset management and solar energy: Driving ROI with data and insights

Downtime is a nuisance. When Balan needed help minimizing both delays and waste, TAG delivered on both fronts.

“With The Asset Guardian (TAG), our downtime has dropped more than 38% compared with prior to implementing CMMS, which adds to the return on investment or the revenue that we're making.”

It’s not just about revenue. TAG and Microsoft Business Central are helping Amin Renewables meet their sustainability mission, too. That kind of operational clarity enabled smarter decision-making.

With TAG’s asset-level tracking, Balan could optimize spare part usage, reduce waste, and ensure inventory was always available when needed on a tablet or directly in the ERP system.

“We are tracking very critical elements which has helped our plant to maintain a pretty robust performance ratio.”

Built on collaboration: the right partners make the difference

Amin Renewables didn’t take this journey alone. Medlar, a trusted Microsoft partner, played a key role in guiding the selection and deployment of both Microsoft Dynamics 365 Business Central and The Asset Guardian (TAG).

Their deep EAM and ERP expertise helped align every layer of the project, ensuring system architecture, data flow, and day-to-day usability all worked together seamlessly.

By relying on Medlar’s specialized knowledge and broader Microsoft partner network, Amin Renewables was able to access proven best practices, implementation sources, and a trusted roadmap for scalable asset management.

Together, TAG, Medlar, and Microsoft delivered a solution that empowers Balan to operate smarter, greener, and more efficiently than ever before. But it was also about preparing for what’s next.

“The Asset Guardian (TAG) provides us with that kind of forward-looking ability.” says Balan.

With enterprise asset management now fully connected to the ERP, Balan and his team can now plan proactively, anticipate future needs, and support continuous improvement. And with tools like Power BI dashboards, Copilot for Business Central, AI-powered insights in TAG Mobi, and IoT-based asset tracking, they now have intelligent systems helping them to stay one step ahead.

Smarter energy starts with the right tools

With TAG and Microsoft Dynamics 365 Business Central working in sync, Balan and his team are staying ahead of failures and keeping production steady. Downtime has dropped more than 38% compared with prior to implementing CMMS. Asset tracking is sharper. Space parts and inventory are managed with greater accuracy. Every insight helps protect performance and every action supports clean energy delivery.

This transformation didn’t happen by chance. It was driven by the right technology, strong partnerships, and Balan’s expertise on the ground. With Balan’s deep maintenance experience guiding the process, the company saw a significant reduction in downtime, smarter spare parts and inventory planning, and real-time asset tracking with automated alerts. The plant became more operationally sustainable, and performance visibility improved across the board.

For companies in solar, renewable energy, or utilities, this success story is a clear example of how the right strategy and tools can unlock real ROI and long-term resilience.

Want to see how TAG can help you reduce downtime, streamline maintenance, and protect your energy output? Contact us today to learn more or schedule a demo.