Creating an Effective Preventive Maintenance Plan: What You Need to Know

Learn how to build a preventive maintenance plan and reduce equipment failure using EAM software.

What you will learn in this article

What preventive maintenance is and how it keeps equipment running smoothly

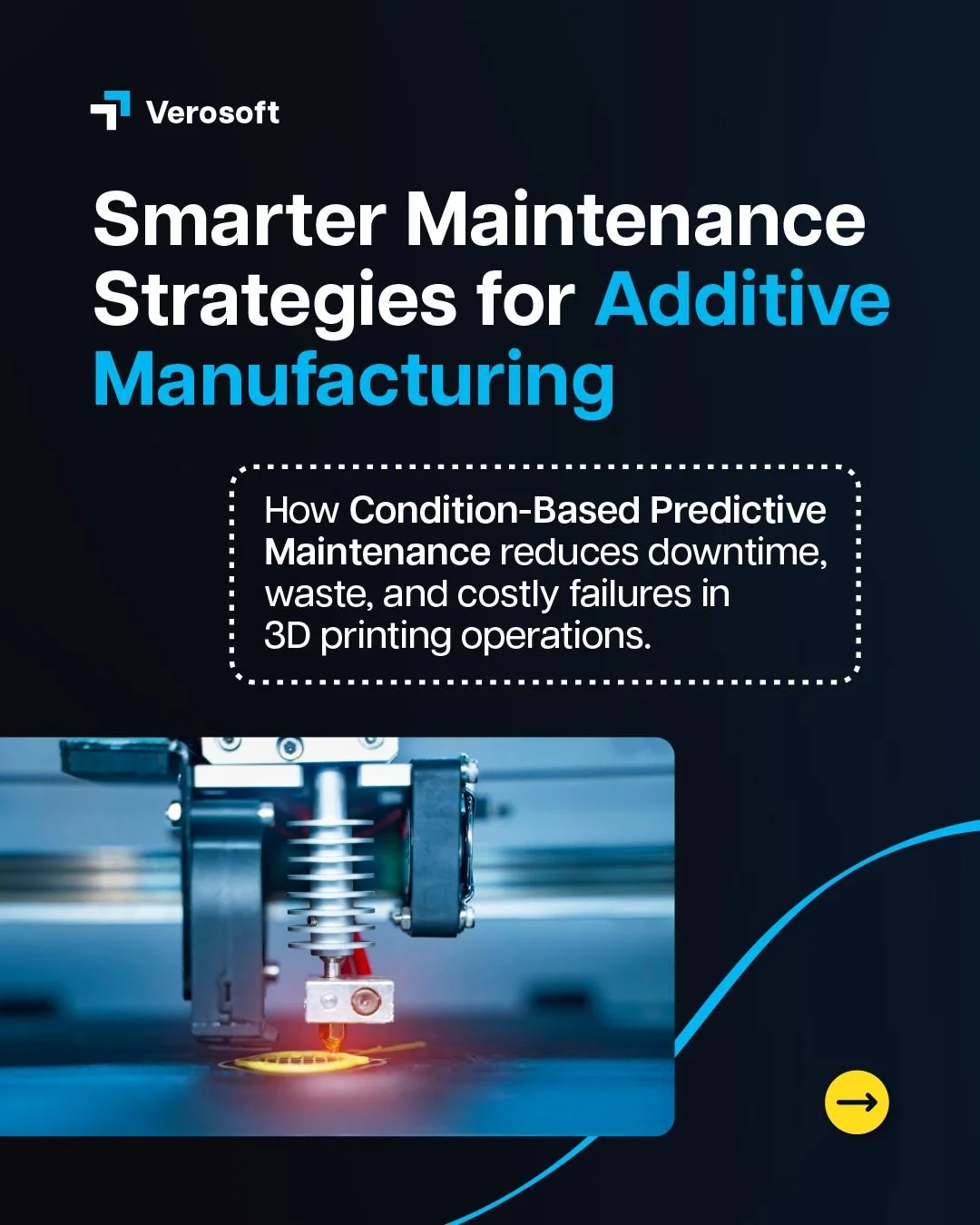

The difference between preventive and predictive maintenance strategies

Why preventive maintenance is critical in asset-heavy industries

The key benefits of using preventive maintenance software

Step-by-step instructions to build an effective preventive maintenance plan

How preventive maintenance fits into a larger Enterprise Asset Management (EAM) strategy

How EAM software like TAG Mobi can streamline your maintenance program

Every 17 minutes, one asset is saved from failure thanks to preventive maintenance. When equipment fails, the impact goes far beyond a repair bill. It can stop production, put safety at risk, damage customer relationships, and lead to serious financial losses. That’s why companies in manufacturing, renewable energy, and facility management are shifting from reactive fixes to preventive strategies. In this article, we’ll explore what preventive maintenance is, how it works, and why investing in preventive maintenance software can be the smartest move you make this year.

What is preventive maintenance?

Preventive maintenance is the practice of performing regular, planned maintenance tasks, like inspections, cleanings, part replacements, or software updates, to prevent equipment breakdowns before they happen. Think of it like changing the oil in your car every 5,000 miles to keep it running smoothly, instead of skipping it and risking a breakdown on the road.

This type of maintenance is scheduled based on time, usage, or condition. For example, you might change a filter every 90 days or inspect a turbine after every 500 hours of operation. These small, routine actions reduce the risk of sudden failures and keep assets performing at their best.

In this article, we’ll explore how preventive maintenance works, how it fits into a broader asset management strategy, and why using the right software, like an Enterprise Asset Management (EAM) platform, is key to creating an effective preventive maintenance plan.

What’s the difference between preventive and predictive maintenance?

Both help you avoid problems, but they work in different ways:

Preventive maintenance is based on time or usage (like every month or after 100 hours).

Predictive maintenance uses real-time data to tell you when something might go wrong.

Many companies use both together to get the best results. In fact, companies that implement predictive and preventive maintenance properly see up to a 30% increase in Mean Time Between Failures (MTBF)[1], meaning their equipment stays up and running longer between breakdowns.

Why preventive maintenance is important

In asset-heavy industries, when one machine fails, it can slow down everything. That’s why preventive maintenance programs are so important. They help you:

Keep equipment working at its best

Save money over time

In fact, unplanned downtime costs industrial manufacturers up to $50 billion each year[2].

A good preventive maintenance program helps you stay in control. It’s part of a bigger process called asset management, which means taking care of all the tools, machines, and equipment your company depends on.

You May Be Interested In…

What is preventive maintenance software

Preventive maintenance software helps you stay organized. Instead of using paper or spreadsheets, you can:

Set automatic reminders for service

Track all maintenance work

See a history of each asset

Assign tasks to your team

Get reports for audits or inspections

Most companies use EAM software (Enterprise Asset Management software), which includes preventive maintenance tools.

Key benefits of preventive maintenance software

Here are some key benefits of using software to manage preventive maintenance:

You save time by automating tasks

You catch problems early before they get worse

You reduce downtime, so work keeps moving

You keep good records of all your repairs

You improve safety by keeping machines in top shape

You stay on schedule, even with a big team

How to create a preventive maintenance plan

Here are 8 simple ways to start a preventive maintenance program:

Define your maintenance goals: Decide what success looks like (fewer breakdowns, lower costs, safer operations, etc.).

Make a list of your assets: Include equipment name, age, condition, location, and past issues.

Choose the most important assets: Start with machines that are expensive, safety-critical, or used often.

Set a maintenance schedule: Follow the manufacturer’s advice or your team’s experience for timing.

Document standard procedures: Write out the steps for inspections or tasks so the work is consistent.

Use software to track the work: This helps you stay on top of tasks, assign jobs, and avoid delays.

Train your team: Make sure everyone knows what to do, how to do it, and when to do it.

Review and improve: Check your progress every few months. Adjust the plan as needed.

How preventive maintenance and EAM work together

So, what is EAM software?

EAM stands for Enterprise Asset Management. It’s a type of software that helps you take care of all your company’s equipment from start to finish.

Preventive maintenance is a big part of EAM. When you use EAM software, you can:

Schedule tasks easily

Manage all assets in one place

Track progress in real time

Make better decisions with reports

If you’ve been asking, “What is preventive maintenance?” or thinking about how to improve your current plan, now’s the time to act.

By using preventive maintenance software and a strong EAM solution, you can cut costs, avoid breakdowns, and keep your operations running smoothly.

Ready to build a smarter, more reliable maintenance program?

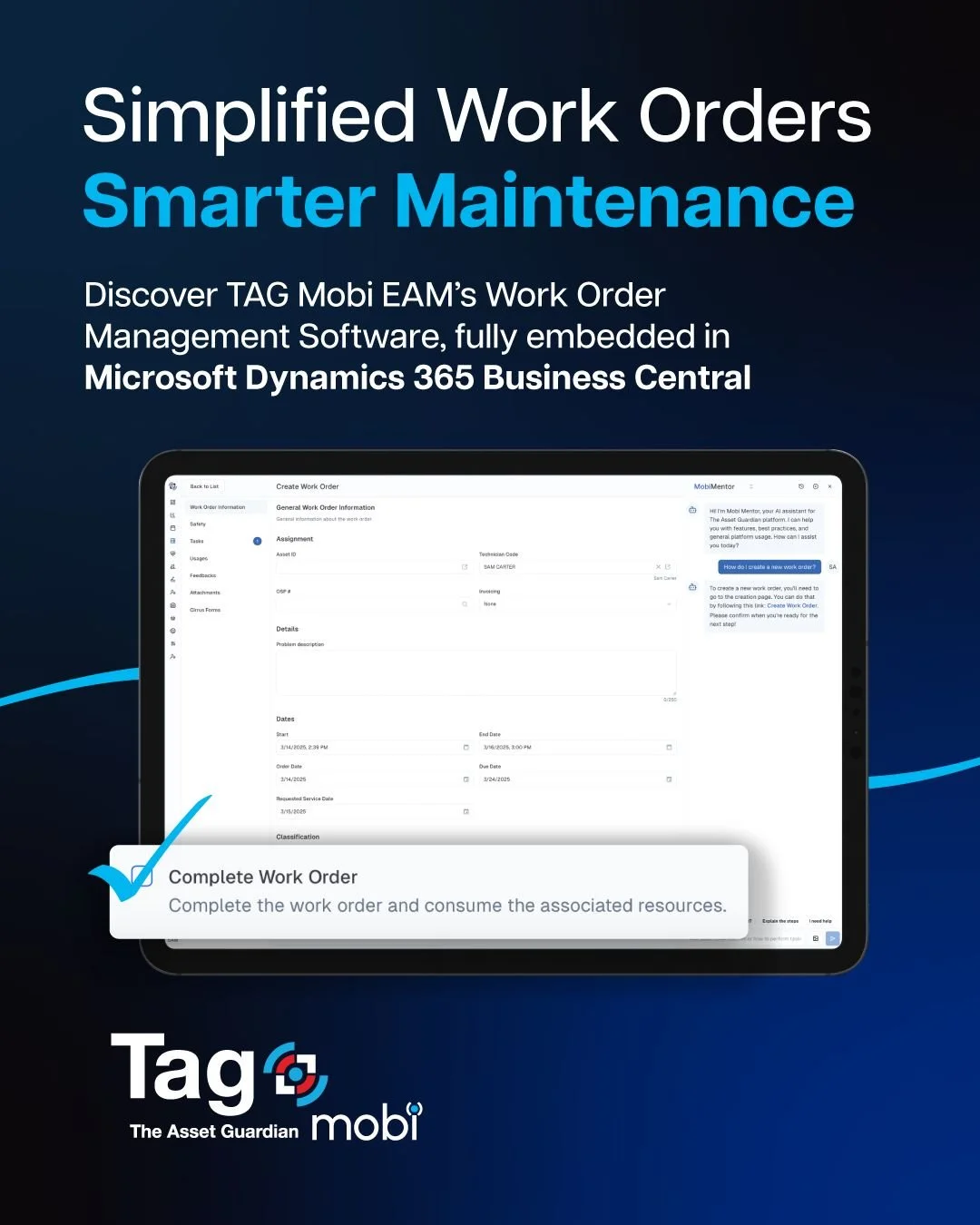

With The Asset Guardian (TAG) Mobi EAM software, you can easily schedule and track preventive maintenance tasks, reduce downtime, and extend the life of your assets all in Microsoft Dynamics 365 Business Central, synced in one centralized system.

Whether you're managing production lines, renewable energy assets, or facility infrastructure, TAG Mobi helps you put the right plan in place and keep your operations running without surprises. See how TAG can support your preventive maintenance strategy by trying a free interactive demo today.

[1] Source: BEMAS, 2025

[2] Source: forbes.com

Continue reading…