What is Asset Performance Management (APM)?

Learn how Asset Performance Management (APM) boosts equipment performance, cuts downtime, and supports smarter maintenance decisions.

What you will learn in this article:

What Asset Performance Management (APM) is and how it helps improve reliability and reduce risk

The role of condition monitoring, predictive forecasting, and reliability-centered maintenance in APM

Why APM matters for industries like manufacturing, renewable energy, and facility management

How APM and Enterprise Asset Management work together

How APM supports preventive and predictive maintenance strategies

Key components of a successful APM program

Real-world benefits and stats that show the value of APM

How TAG Mobi EAM helps you put APM into action using real-time data and automation

Asset Performance Management (APM) is a data-driven approach for improving how your physical assets perform over time. It brings together data capture, integration, visualization, and analytics with one goal in mind: to increase asset reliability and availability.

Asset performance management software isn’t just about scheduling maintenance, it’s about understanding the full picture of asset health and using that insight to make smarter decisions. It includes practices like condition monitoring, predictive forecasting, and Reliability-Centered Maintenance (RCM) to help organizations move from reactive to proactive operations.

Think of an asset performance management system as the bridge between asset data and business outcomes. It helps businesses know not just when to act, but why, where, and how to maximize uptime, reduce risk, and avoid unnecessary costs.

In this article, you will learn how asset performance management works, why it matters, and how you can apply it to reduce downtime, improve asset reliability, and make smarter maintenance decisions.

Why asset performance management matters

Unplanned asset downtime can cost manufacturers thousands per hour. That’s why forward-thinking companies are turning to Asset Performance Management (APM) to stay ahead of breakdowns and optimize equipment reliability.

Asset performance management plays a key role in enabling predictive maintenance strategies, which use real-time data to spot issues before they escalate. When implemented properly, these programs can increase Mean Time Between Failures (MTBF) by up to 30%[1], meaning equipment stays operational longer between breakdowns.

Every machine tells a story. But without APM, most companies can’t listen. In industries like manufacturing, facilities, and renewable energy, even one failure can halt production lines, create safety risks, and trigger expensive emergency repairs.

Here is why Asset Performance Management is gaining traction:

It reduces unplanned downtime, which costs manufacturers billions annually

It helps your equipment last longer, so you don’t have to buy new machines as often

It improves safety and compliance through better monitoring

It gives you better data to make smarter maintenance and budget decisions

The financial implications of unplanned downtime are staggering. A study by Senseye Predictive Maintenance found that large plants experience costs averaging $532,000 per hour due to unplanned downtime [2]. Adopting an asset performance management system can significantly reduce these expenses by enabling proactive maintenance strategies.

Core components of an APM program

A strong Asset Performance Management strategy pulls together several key elements.

1. Asset health monitoring

Use sensors, meters, and mobile inspections to capture asset conditions in real time.

2. Performance optimization

Analyze trends in availability, cost, and reliability to improve outcomes and identify gaps.

3. Maintenance planning

Move from reactive to planned and predictive actions based on risk, usage, and impact.

4. Failure prediction

Leverage machine learning or historical data to anticipate failures before they happen.

5. Work order and asset history

Track everything that happens to each asset for better compliance and smarter scheduling.

6. Downtime and KPI reporting

Monitor MTBF, availability, costs, and other critical KPIs in dashboards to guide decision-making.

Benefits of asset performance management

Asset performance management is not just about fixing machines; it’s about making smarter decisions with your assets. It helps you move from reacting to problems to planning ahead, so your maintenance team adds value instead of just putting out fires.

Implementing asset performance management pays off in multiple ways.

More uptime: Catch failures before they happen

Lower costs: Spend less on emergency repairs and unnecessary replacements

Smarter maintenance: Focus on the right tasks at the right time

Stronger insights: Know which assets are helping or hurting your bottom line

Longer asset life: Optimize usage and avoid early replacement

How APM and EAM work together

EAM (Enterprise Asset Management) systems help you manage your assets and asset performance management helps you get more value from them. While EAM gives you the structure to plan, schedule, and document asset activities, APM brings in the analytics layer. Together, they give you both visibility and intelligence.

How asset performance management supports preventive and predictive maintenance

Asset performance management and maintenance aren’t separate strategies, they’re partners. APM helps you fine-tune your preventive maintenance plan by identifying:

Which assets need frequent checks

Where your failures are really coming from

How to balance effort vs impact

If you’re just getting started with preventive maintenance, check out our guide on creating an effective preventive maintenance plan to build a solid foundation that APM can help you optimize.

5 steps to getting started with asset performance management

List your most critical assets and their known risks

Review past performance data to identify patterns

Set up regular condition monitoring (even basic forms)

Define KPIs to measure what “good” looks like

Use EAM software like TAG to track, analyze, and act on data

Asset performance management and TAG Mobi EAM

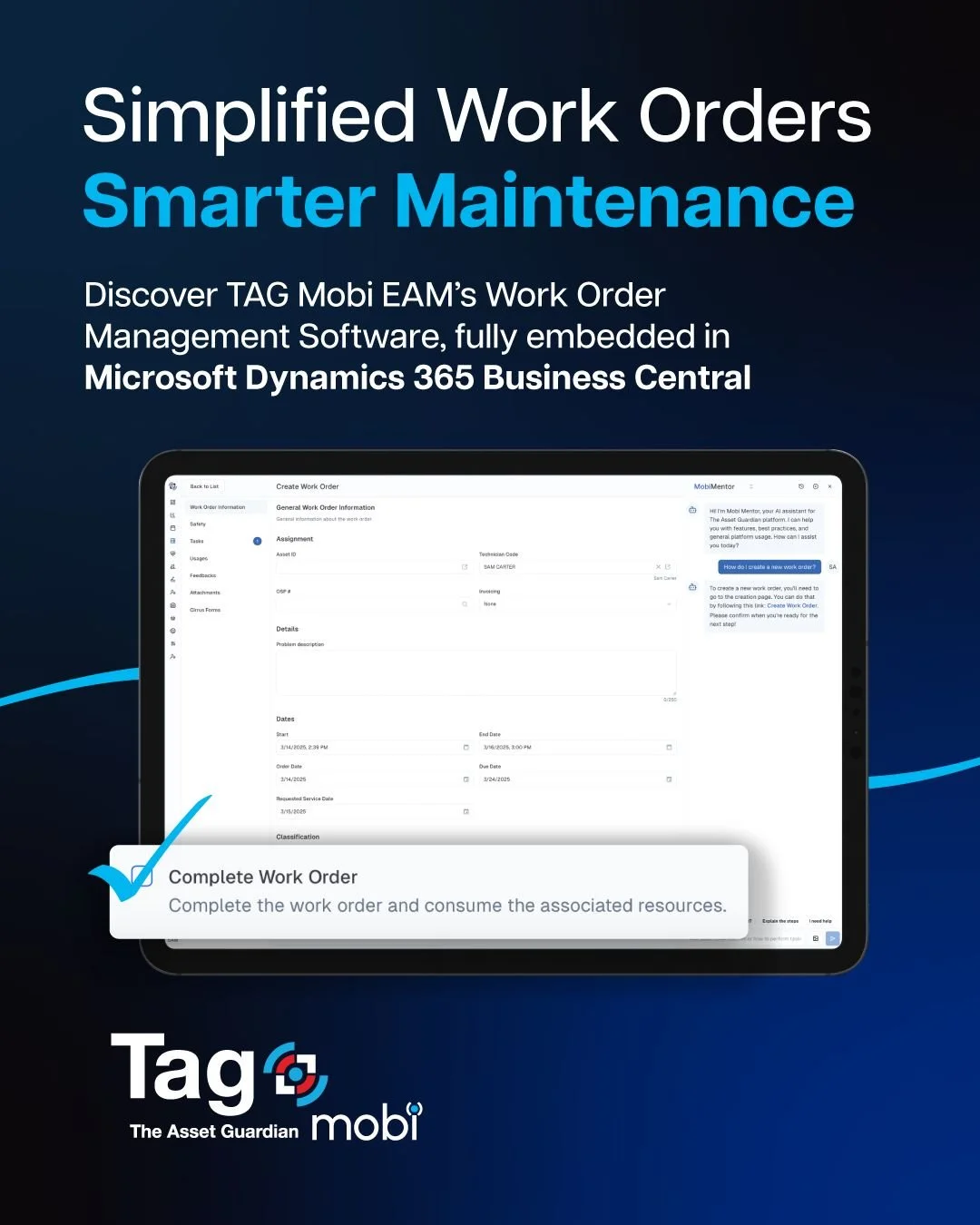

TAG Mobi EAM brings asset performance management principles into the field and into your Microsoft ecosystem. Here’s what that looks like:

Mobile-first inspections to feed real-time asset data

Work history tracking for smarter future decisions

Automated scheduling based on usage, risk, or failure rates

Downtime logging and reporting to uncover problem trends

Seamless integration with built in Microsoft Dynamics 365 Business Central

Ready to improve asset reliability and reduce costly breakdowns?

TAG Mobi EAM gives you everything you need to build a smart, scalable asset performance strategy that fits your operations, whether you're in manufacturing, renewable energy, or facility management. Explore TAG Mobi’s features to see how condition monitoring, performance tracking, and preventive maintenance tools work together in one platform. Or try a free interactive demo to experience how easy it is to manage asset performance with TAG Mobi in action.

[1] Source: BEMAS 2025

[2] Source: siemens.com/senseye-predictive-maintenance