35 Must-Know Maintenance Abbreviations and Acronyms

A complete glossary of essential acronyms for EAM, CMMS, APM, and more. Plus, a bonus section for extra clarity.

What you will learn in this article:

Maintenance and reliability acronyms

Core asset management acronyms

Financial, operations, and IT acronyms

Compliance, safety, and environmental acronyms

Field and mobile work acronyms

Bonus acronyms

Are you swimming in a sea of confusing maintenance acronyms? Don’t worry, you’re not alone! Whether you’re just getting started in maintenance or have decades of experience under your belt, it’s easy to get lost in a maze of terms and abbreviations that pop up across enterprise asset management, reliability, and operations.

That’s why we’ve put together this quick-reference list of the most essential acronyms you’ll encounter in discussions, documents, and software systems across the industry. Plus a bonus section of acronyms related to vendor contracts, APIs, and corrective work.

Bookmark this page for your next meeting or when that mysterious acronym appears in your inbox.

Maintenance & Reliability Acronyms

Used by maintenance teams, reliability engineers, and operations planners, these acronyms reflect key metrics and strategies to keep equipment running longer.

WO: Work Order

The official job ticket for maintenance tasks. Generated from EAM/CMMS systems.

PM: Preventive Maintenance

Scheduled maintenance based on usage, calendar intervals, or manufacturer guidelines.

PdM: Predictive Maintenance

Uses real-time data from sensors to catch problems early. Helps avoid unplanned downtime and extend equipment life.

MTTR: Mean Time to Repair

How long it takes to fix something once it breaks. A critical benchmark for service teams.

MTBF: Mean Time Between Failures

Shows how long equipment runs before failing. Useful for evaluating asset reliability.

MTBM: Mean Time Between Maintenance

The average time between scheduled maintenance tasks, helping assess efficiency and planning needs.

RCM: Reliability-Centered Maintenance

A structured strategy that balances preventive, predictive, and corrective maintenance based on risk and asset criticality.

CBM: Condition-Based Monitoring

Ties maintenance to real-time asset conditions like vibration, temperature, or oil quality.

MRO: Maintenance, Repair, and Operations

Activities and materials used to keep equipment running.

OEE: Overall Equipment Effectiveness

Combines availability, performance, and quality into one metric to evaluate production efficiency.

RCA: Root Cause Analysis

A structured problem-solving method used to identify the underlying cause of a failure or issue.

FMEA: Failure Modes and Effects Analysis

A proactive approach to identifying potential failure points in a system and assessing their impact.

PMO: Planned Maintenance Optimization

A strategy to refine and prioritize preventive maintenance tasks based on equipment history and risk.

OEM: Original Equipment Manufacturer

Refers to the company that originally produced the asset or component, often referenced for parts and specifications.

RPN: Risk Priority Number

A score used in FMEA to rank potential failures based on severity, occurrence, and detection difficulty.

FMECA: Failure Modes, Effects, and Criticality Analysis

An extension of FMEA that also ranks how critical each failure mode is to prioritize response.

Core Asset Management Acronyms

These are the foundational terms you’ll see across platforms, proposals, and conversations about maintenance and asset lifecycle management.

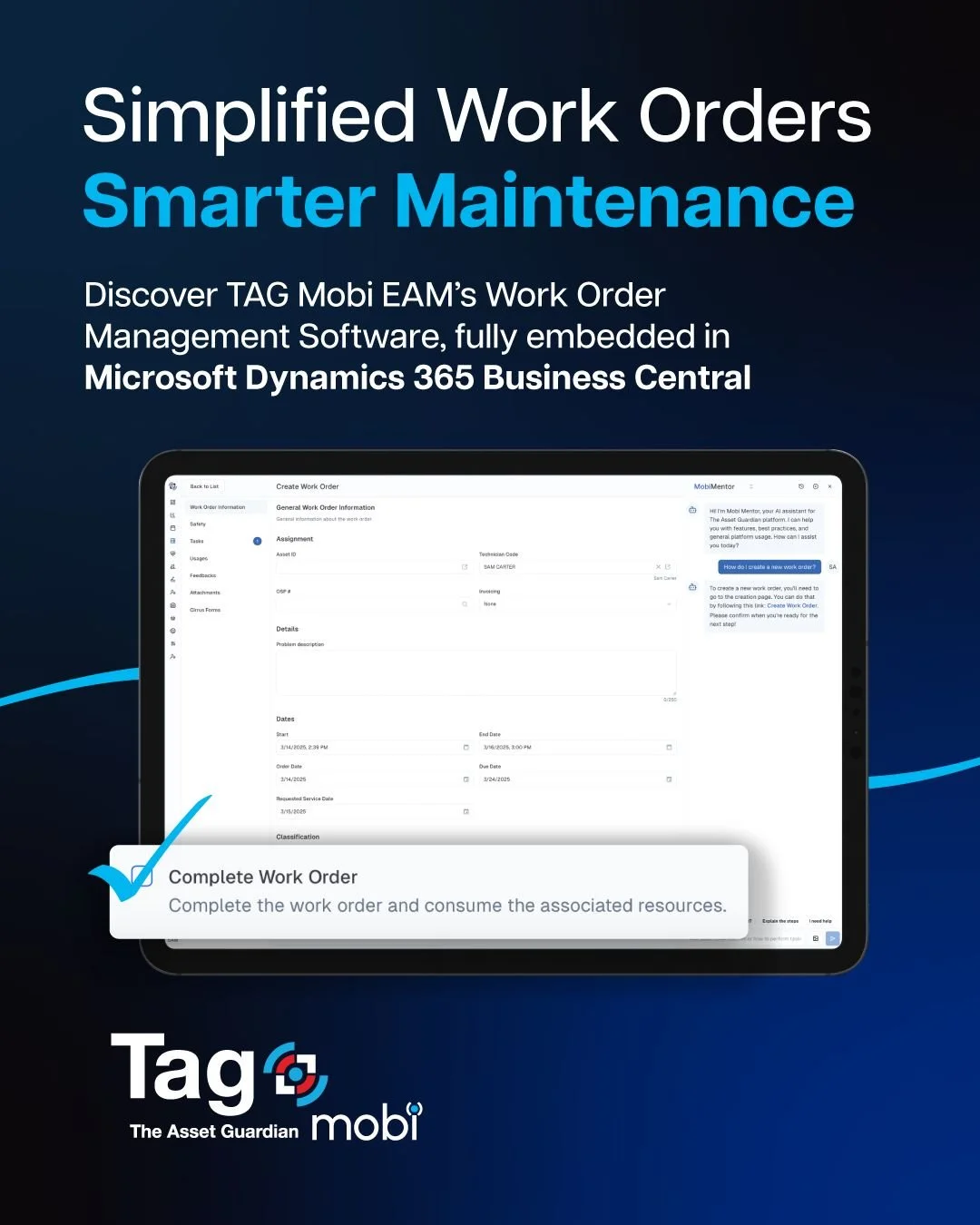

EAM: Enterprise Asset Management

Software used to manage the entire lifecycle of an organization’s physical assets. Learn more.

CMMS: Computerized Maintenance Management System

A type of software focused on tracking maintenance activities like work orders, scheduling, and repairs.

APM: Asset Performance Management

Tools and practices that help monitor and improve how well assets are operating.

TPM: Total Productive Maintenance

A maintenance approach that involves operators, technicians, and managers in keeping equipment running efficiently and preventing failures.

Financial, Operations, and IT Acronyms

These acronyms come up when maintenance and asset management connect to budgeting, planning, and regulatory oversight.

ERP: Enterprise Resource Planning

Business software that manages core processes like finance, purchasing, inventory, and operations in a single system.

SCADA: Supervisory Control and Data Acquisition

A system used to monitor and control industrial processes, often collecting real-time data from equipment and sensors.

KPI: Key Performance Indicator

A quantifiable metric used to track progress toward maintenance and operational goals.

TCO: Total Cost of Ownership

A comprehensive figure that includes acquisition, operation, maintenance, and disposal costs.

ROI: Return on Investment

Measures whether an initiative, like switching to predictive maintenance, yields financial value.

GRC: Governance, Risk, and Compliance

A framework that ensures regulatory obligations and internal policies are met.

IoT: Internet of Things

Devices that collect and exchange data. In EAM, IoT enables predictive and condition-based maintenance.

Compliance, Safety, and Environmental Acronyms

EHS: Environment, Health, and Safety

Policies and practices focused on protecting workers, the environment, and operational safety.

ISO: International Organization for Standardization

An international body that publishes standards for quality, safety, and operational consistency.

OSHA: Occupational Safety and Health Administration

A regulatory agency that sets and enforces workplace safety standards.

LOTO: Lockout/Tagout

A safety procedure that ensures machinery is properly shut down and not restarted during maintenance or repair.

Field and Mobile Work Acronyms

These show up when assets are in remote locations or serviced on the go.

GIS: Geographic Information System

Software that maps and analyzes asset data based on location, commonly used in utilities and infrastructure.

RFID: Radio Frequency Identification

Technology that uses radio waves to track assets, tools, or inventory automatically.

GPS: Global Positioning System

Satellite-based technology used to track asset or technician locations in real time.

Bonus Acronyms

API: Application Programming Interface

A set of rules that allows different software systems to communicate and share data with each other.

CM: Corrective Maintenance

A basic but often-overlooked term that simply refers to fixing something once it breaks.

SLA: Service Level Agreement

Often found in vendor contracts for uptime or repair timelines.

Acronyms have become second nature in asset management. If you’re out in the field, leading a team, or sorting through reports, you’ll run into them all the time. Being familiar with these terms makes it easier to understand each other and get things done.

Bookmark this list for your next meeting or pass it along to your team. The more familiar these acronyms become, the more confident your decisions can be.

If you’re noticing these acronyms more in your daily work, it could be a good time to check in on your asset management tools. Are they making it easy to track, plan, and see what’s happening, or are you stuck juggling several different systems?